Cruise Ship Propeller Cost

A revolution in ship propulsion technology.

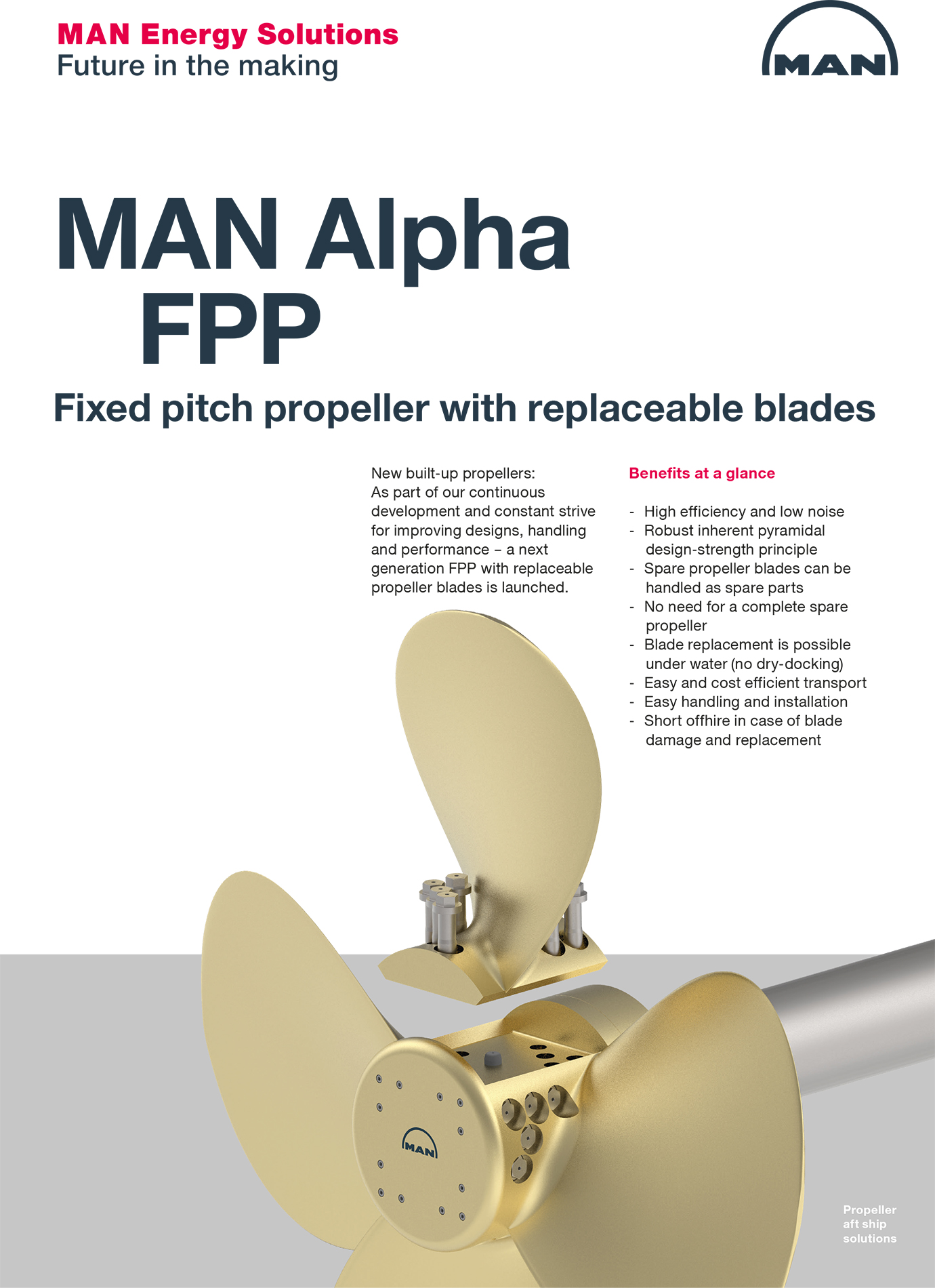

Cruise ship propeller cost. The trials have shown that the Energopac solution saves close to 4 per cent power in design condition. There were three propellers in this ship weighing 38 tons each. This represents annual fuel cost savings of more than USD 120000 at fuel prices in July 2010.

At the shipowners request Thordon Bearings the market leader in water lubricated bearing. Seawise Giant was the longest ship ever built. The most fun fact of all in this category is the berth price of one of the worlds most expensive big cruise ships - the most famous Cunard liner RMS Queen Mary 2 2004-built with a berth cost of over the USD 300000 - the industrys highest-ever.

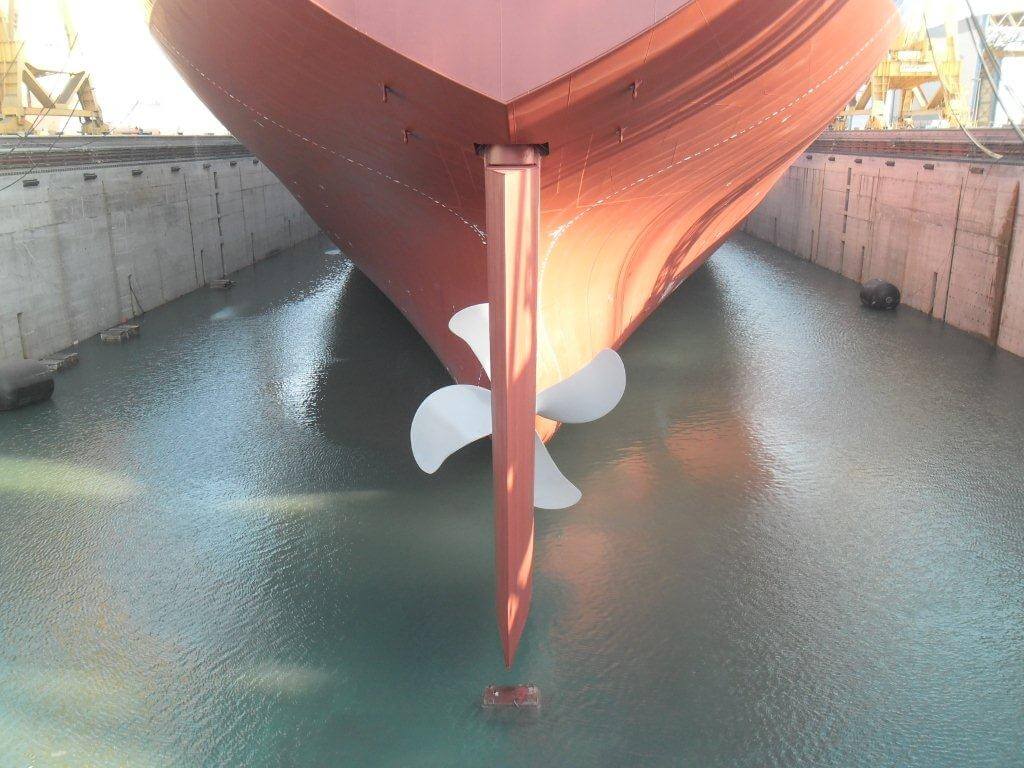

The difference between the nominal. All cruise ships rely on propellers to push them through water. The prop has to hold up to millions of miles of travel and move the ship fast enough to get from port to port on time.

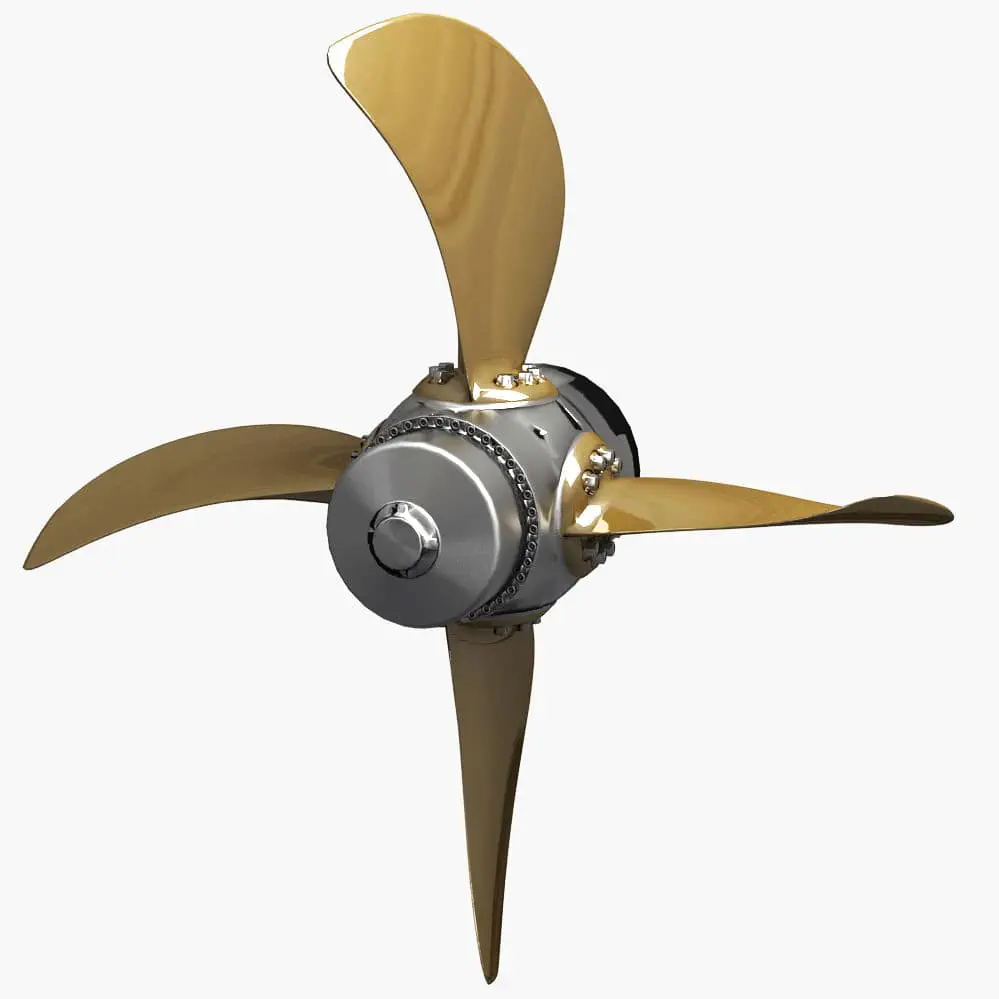

In this aspect the hull form of. Cruise ships are built because they are big businesses. Propellers and Rudders Ducted propeller 10 all ship types except ferry and cruises medium 4-15 years Medium Propellers and Rudders Contra-rotating propellers 13 only special ship types long 15 years High Propellers and Rudders Wheels 10 all ship types except ferry and cruises short.

Also the wake field behind the propeller is close to optimal. In reality since the propeller is attached to a shaft it will not actually move forward but instead propel the ship forward. Lines price the cruise ships building cost by the number of beds the marine term is berths.

The pulling propeller eats from the homogenous field of water. An upgrade that the company said will significantly reduce operating costs for Hurtigruten. A recent inspection of the twenty-year-old water-lubricated propeller shaft bearings installed on a twin-screw cruise ship were found to be within classification society parameters and suitable for continued use for a further ten years of operation.